Manufacturing, Quality Control & Workplace Safety

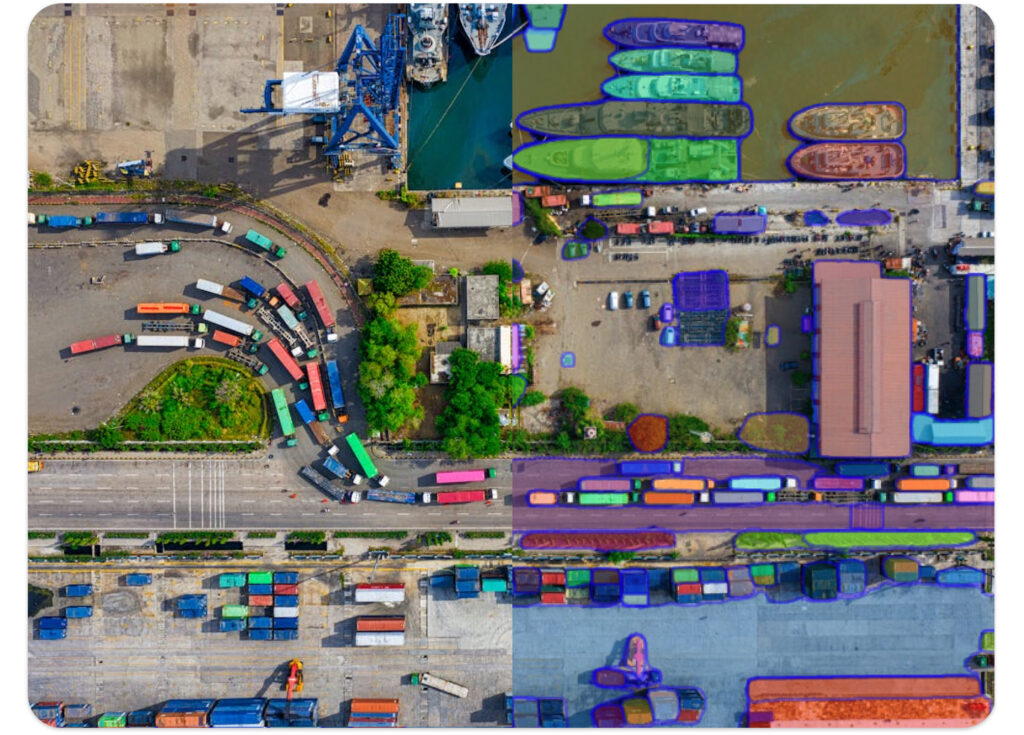

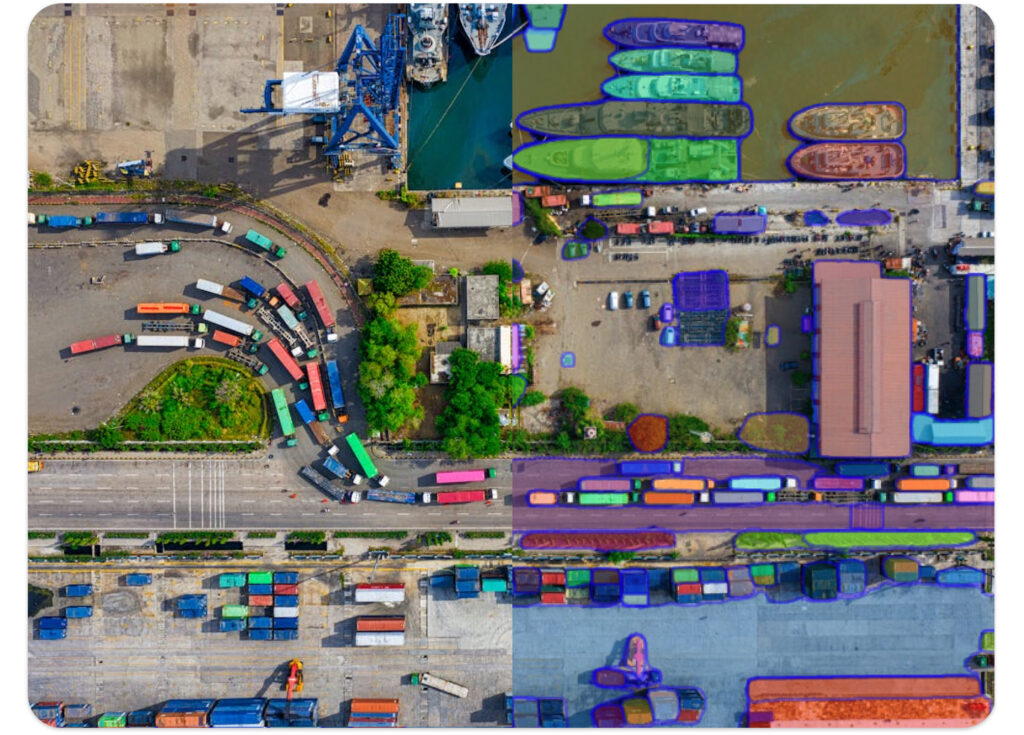

Ensure a secure, efficient, and compliant work environment. Visual AI monitors real-time hazards and automates product counting, packaging checks, and tracking of vehicles and personnel.

Automate tasks with AI

Cut Costs, Boost Efficiency, and Improve Transparency

Incorporating Artificial Intelligence into your production line or surveillance system can lead to substantial cost and energy savings, reduced failure rates and enhanced process transparency.

AI-driven solutions such as image classification, tagging or object detection can be used to automate routine tasks and streamline your workflow.

Automate tasks with AI

Automate Quality Control with Visual AI

AI is transforming quality control in manufacturing with advanced visual inspection systems. Using image recognition and object detection, AI can identify defects and anomalies more accurately than human inspectors.

This improves product quality, reduces waste, and cuts costs. From electronics manufacturing and semiconductors to wind farms, many industries now use AI for automated inspections, enhancing efficiency and maintaining high standards in both production and maintenance.

Safety & Security

Strenghten Security & Optimize Compliance

Visual AI enhances workplace safety by monitoring real-time footage for hazards and unsafe behaviours. It alerts staff to potential risks, helping to prevent accidents and ensure adherence to safety protocols.

Tracks access points and detect unauthorized personnel, preventing breaches and suspicious activities. Visual AI helps secure sensitive areas and facilitate compliance with regulations.

Offline AI

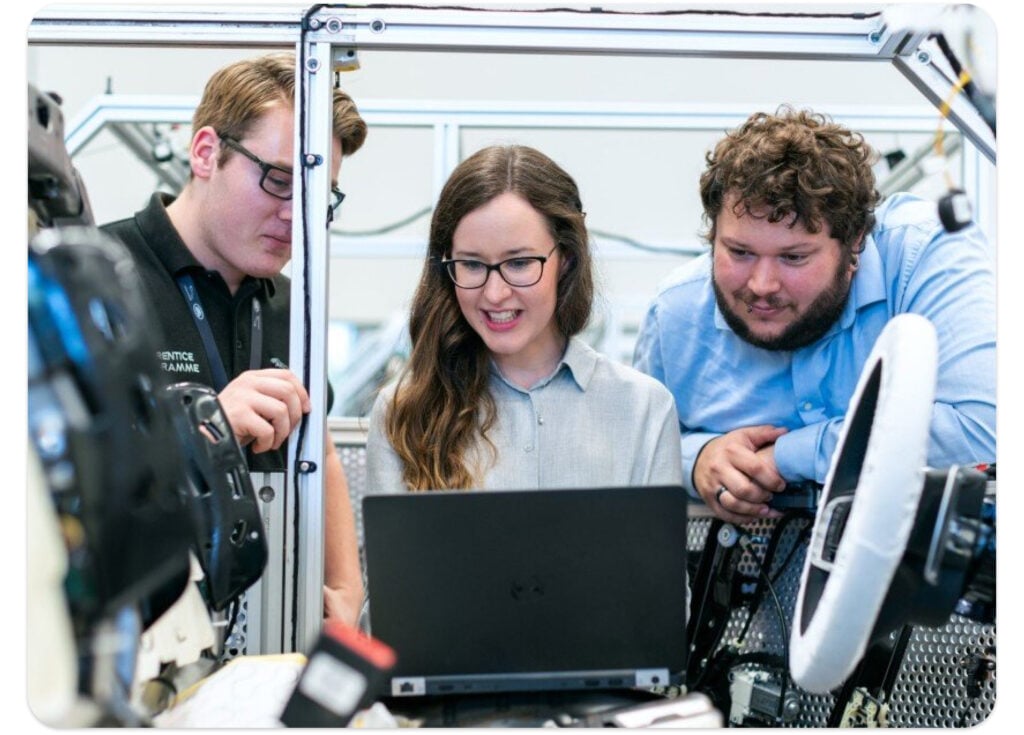

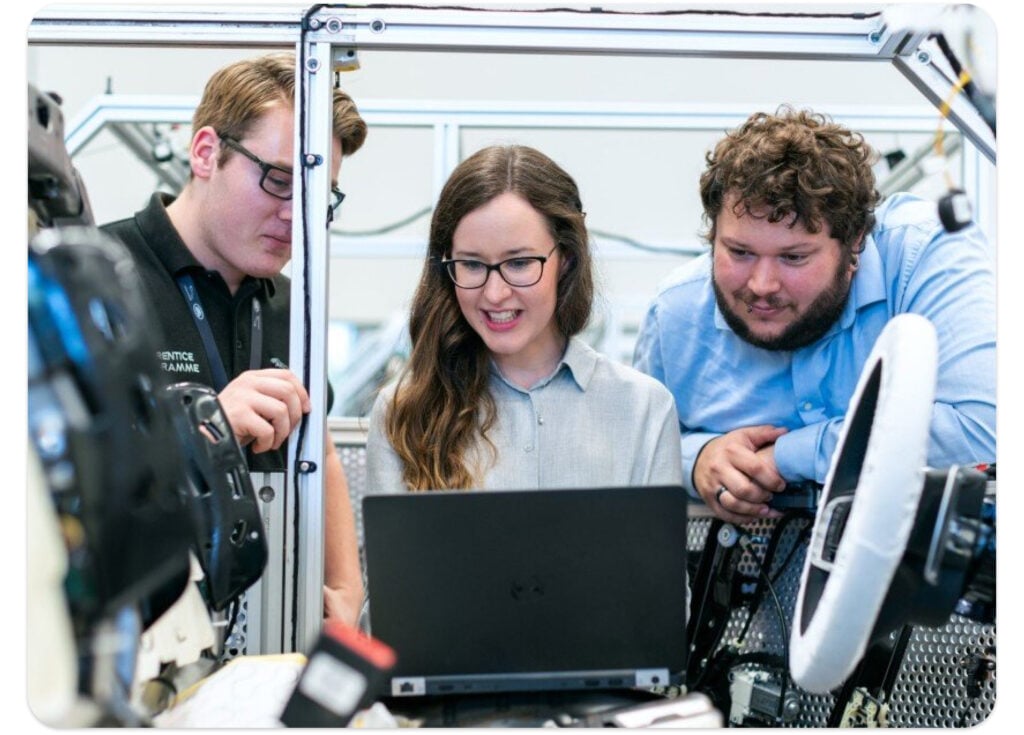

Deploying AI Models Offline in Factories

Using visual AI offline in your production or inspection line offers advantages like enhanced control, reduced latency, and improved data privacy without requiring internet access.

Models can be deployed on modern edge devices, such as the NVIDIA Jetson, which provides real-time processing from camera feeds monitoring your factory’s production line.

Tips & Tricks

How to deploy object detection on Nvidia Jetson Nano

We developed a computer vision system for object detection, counting, and tracking on Nvidia Jetson Nano.

Visual AI Takes Quality Control to a New Level

Comprehensive guide for automated visual industrial quality control with AI and Machine Learning. From image recognition to anomaly detection.

Is Ximilar Better Than AI Giants?

Comparison of pricing and features of main cloud players in computer vision, machine learning and artificial intelligence.

Ximilar is a reliable & responsible partner in image AI. We deliver what we promise.

Contact us now- Easy setup

- •

- Expert team

- •

- Fast scaling